What is Water Jet Cutting?

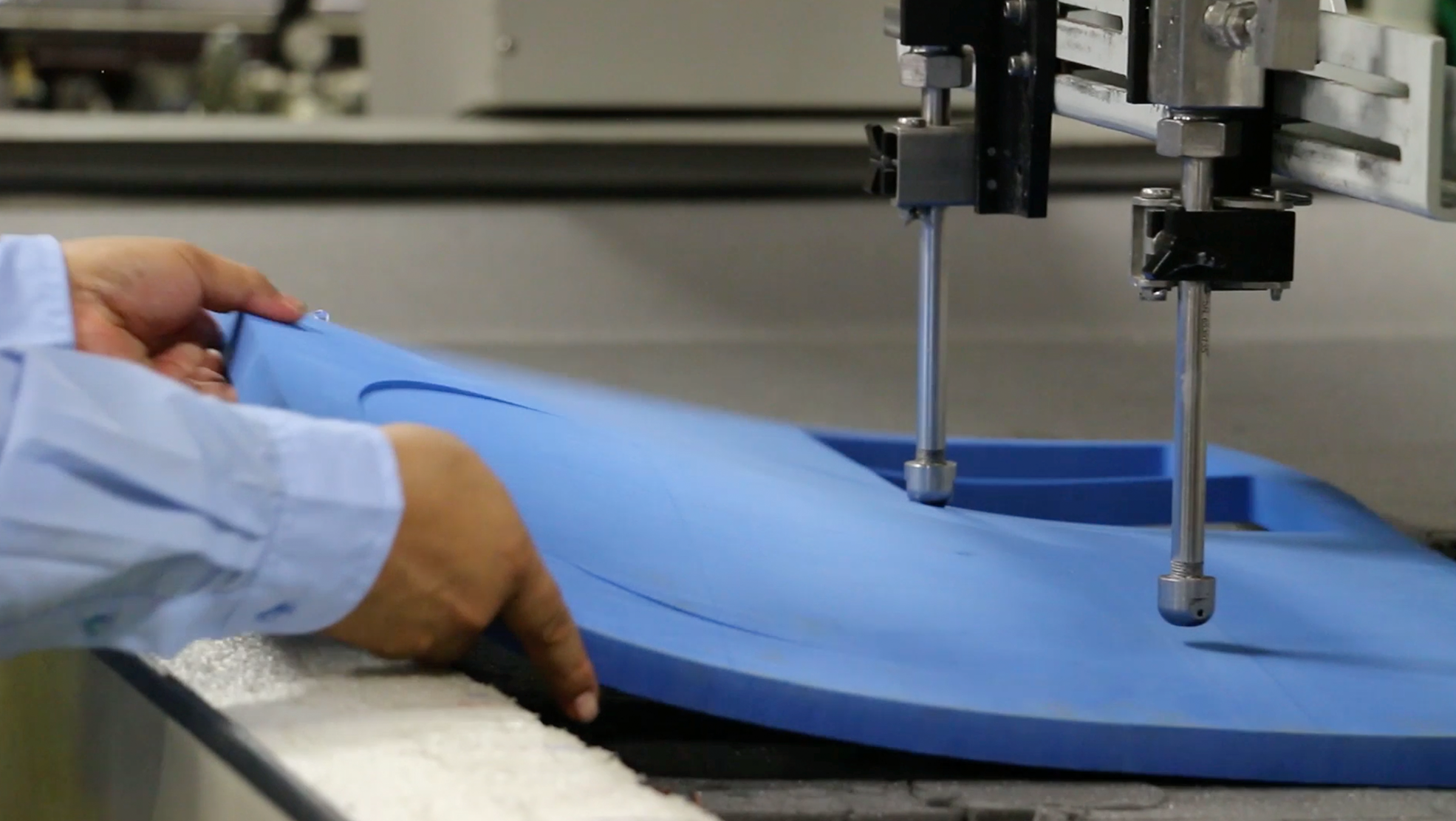

A water jet cutter is an industrial machine that is capable of cutting a wide variety of materials using a very high-pressure jet of water. With the power behind the stream of water, this tool can cut a variety of shapes and sizes in the matter of minutes.

I have seen a water jet cut through wood, plastic, rubber, and foam. The precision is amazing and lines and edges are straight and clean. Water jet cutting is an asset to any foam converting company as it can perform a wide variety of cuts in various media, and leaves no distortion and no edge concavity. Depending on the material, the water jet can cut up to 8″ in thickness.

So, How Does it Work?

The water jet runs off of a computer CAD program which intakes the information, sends the file to the machine, and the jets cut the material into any shape that you draw. With a 60,000 PSI stream of water, water jet cutting can cut through thick materials. The water is stored in a self contained water purification system which reuses it over and over again. This method of recycling the water is sustainable and conserves on water usage.

Madison Polymeric Engineering uses water jet cutting for numerous applications. For more information ⇒ MPE Water Jet PDF