Madison Polymeric Engineering Applications

Madison Polymeric Engineering started as a protective packaging company over 30 years ago and has morphed into a medical products manufacturer and parts manufacturer. We still are considered a protective packaging design and manufacturing company and in addition, we make custom case inserts for sales demonstration, computers and peripheral equipment, environmental monitoring equipment, oceanographic measuring equipment, broadcast and video equipment, insulated food and beverage containers, and military packaging.

Our EPS department produces thermal packaging for shipping frozen pies all over the USA as well as food and beverage 6 panel insulated cartons. A large part of our business is designing and manufacturing EPS candle shippers for the USA’s largest candle manufacturers.

Our urethane department produces cushioning packaging to protect light to medium heavy products throughout the shipping cycle. Urethane foam is excellent for protecting glass products, sensitive electronic products which are bagged, award products, and medical post op foam positioners and immobilizers.

Our polyethylene department produces end caps to support products in a carton during the shipping cycle, custom case inserts for drones and other electronic devices. Cross-linked polyethylene can be used for pool toys, medical products which must be closed cell to prevent bacteria and foreign objects from getting embedded in the foam.

Both urethane and polyethylene foams are available in anti-static versions or static dissipative materials to protect sensitive electronic components from static electric discharges which may damage the product.

Madison Polymeric also has several pouch filling lines, two of which are automated. We can automatically fill enzymatic solution or other liquid treatments into pouches, drop in a foam applicator and seal the pouch in-line. We are always interested in filling pouches with solution for new customers. Once the pouches are filled and sealed, we load them in printed cartons and palletize them, ready for shipment.

FOAM PROTECTION FOR VALUABLE PROPERTY

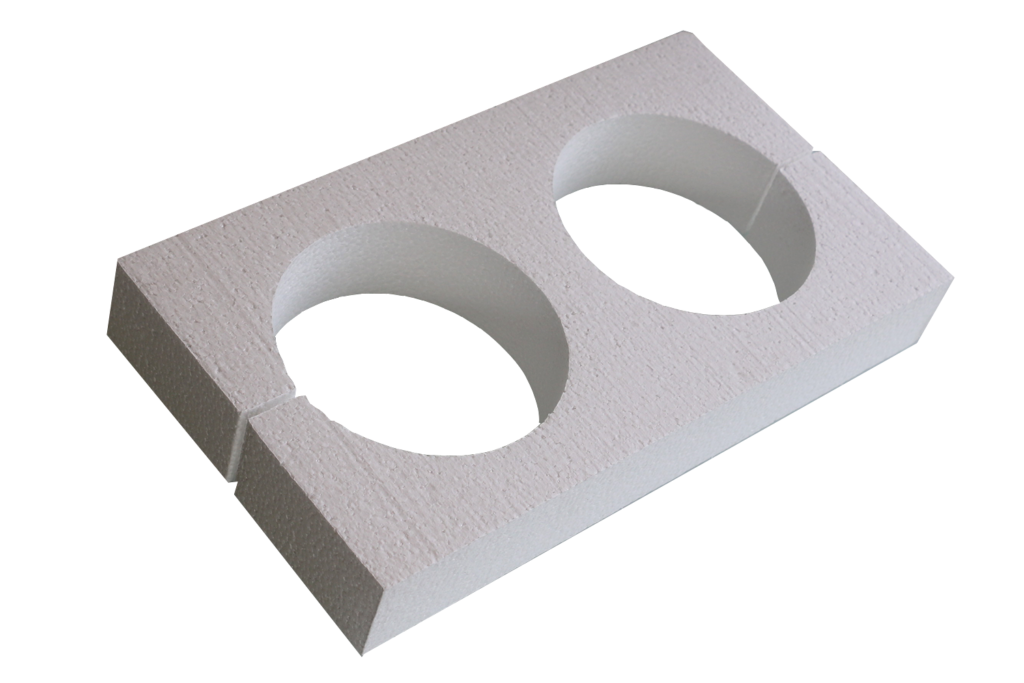

One of the most common uses of Madison Polymeric Engineering’s custom foam is as a case insert to protect and display delicate and valuable equipment. A custom foam insert presents your product in a clean, professional way that packing peanuts and bubble wrap don’t offer. It’s ideal for a sales presentation case or a case for a finished product.

Our experienced team can design a foam insert that accommodates your product. Your insert can be ductile to allow for repeated removal and replacement, and you can choose from a variety of materials and colors, including flocked foams for a more polished look.

AN ENDLESS VARIETY OF FOAM INSERTS

You get an endless variety of foam possibilities when you work with us. Our engineers have designed foam products for all kinds of applications, and our water jet cutting, profile cutting and die cutting techniques allow us to make nearly anything.

STORAGE SOLUTIONS & PROTECTIVE PACKAGING DESIGN

Madison Polymeric Engineering is your complete storage solution company. You can have us provide a completed case with your custom foam inserts.

- Fabricated cases

- Soft cases

- Wood boxes

- Die cut cases

- Corrugated boxes

- Molded cases

Our water jet cutter allows us to create a sample quickly without expensive cutting dies, so your costs and delays are minimized.

COMMON PADDED CASE INSERT APPLICATIONS

- Computer and peripheral cases

- Oceanographic measuring instruments

- Environmental monitoring equipment

- Fluorescent light sources

- Meteorology equipment

- Scientific item storage

- Custom case inserts

- End caps

- Crate inserts

- Sales demonstration cases

- Cushioned packaging

- Broadcast and video equipment cases

- Military and law enforcement cases

FOAM PRODUCT COMPONENTS

- Athletic equipment

- Water toys

- Food and beverage coolers

- Reusable containers

- Surfboard shaping foam

- Insulating foam pads

Explore our Medical Applications

Explore our Packaging Applications