A large part of what we do here at Madison Polymeric is design and manufacture case inserts, often used to protect high value items or present sales materials. A custom case insert is a sales tool for your staff, making you look good but also protecting your samples and products in transport. This saves time and money in the sales process.

Here, Walter takes a look at some options, whats on the market, and what we do here that can help you save money, prevent costly damage and make a better sales impression.

Medical Foam Products

Additional 40,000 Square Feet To Be Added to Connecticut Facility

In response to increased demand, we are pleased to announce we are adding 40,000 square feet this year to our Connecticut facility. This will be done in stages, with approximately 10,000 in May staring the expansion. The additional space will house new equipment we will announce in the near future!

MPE Expands Production Capacity

The completed installation of our new Baumer Precision Skiving Machine has been a high point for Madison Polymeric!

This machine has exceeded our expectations in providing extremely accurate skiving capabilities on high density XLPE, Bead Molded PE and PP along with 9# Extruded PE foam plank, and provides less waste and increases efficiency, as well as truly spectacular precision in your parts.

Please reach out to Madison Polymeric Engineering for help with your precision skiving needs.

Update on Pricing Fluctuations, Supply Chain

In our previous email to our clients, we detailed the issues associated with the supply chain issues the industry is facing, from not only a pricing standpoint but also availability. For example, urethan foam was being distributed only by allocation.

The good news is this appears to be softening, and pricing is beginning to level off. During this time , Madison Polymeric has worked to leverage multiple suppliers to maintain finished product delivery for our clients; at the same time, we are remaining cautious of price fluctuations in PE Foam, EPS Foam and paper board products.

Madison Polymeric to Add Pregis Custom Foam-In-Place Capabilities

Madison Polymeric Engineering (MPE) is excited to announce that we are now an authorized Pregis In-House Pre-Molder of custom engineered Foam-In-Place packaging in the New England market area.

For 2021, MPE continues to expand our protective packaging product offering to create a wide range of options in packaging solutions, providing increased protection with cost savings.

To this end, MPE has completed the installation of the latest generation of Pregis “On Demand” foam-in-place systems allowing us to offer a new Pre-Molded FIP solution to our customers. A foam-in-place production service for the in-house manufacture of custom designed FIP cushioning in low to large volumes where a Pre-Molded Foam In Place part is preferred.

The benefit to you is:

- An ability to see cost savings without the up-front equipment costs

- Manufacturing in a safe material environment

- Cost savings of a larger order for smaller demands

With this new option manufactured at our Branford facility, we can provide the perfect option for customers who do not have the space, time, or the volume to justify in house FIP molding production.

For more information on how the MPE design team can create packaging solutions to meet your needs, contact us today.

Medical Foam Parts

When you have medical foam parts manufactured by Madison Polymeric Engineering, you get the benefits of over 40 years of experience and more than 10,000 unique packaging and medical projects. We have over a million dollars in materials and extensive production capabilities. We can provide any packaging you need.

Call for a FREE quote.

Phone:

203-488-4554

Some of the typical medical products that we fabricate are positioning foams for patients that require holding an arm or leg at a certain angle for scanning or procedural operations. MPE Positioners -> PDF

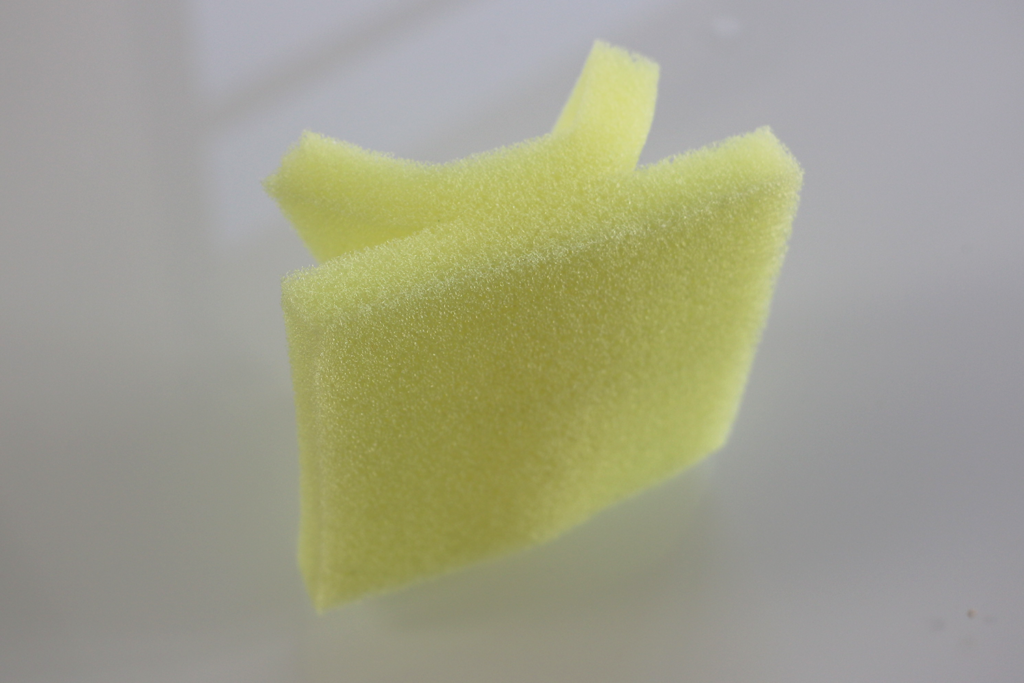

Custom medical products include Scope cleaning sponges, they can be bagged with enzymatic solution for custom private label applications.

Wing sponges are used for applying ointments and topical treatments.

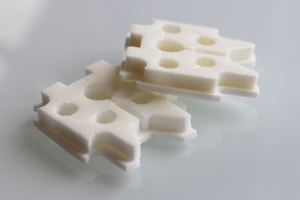

When a closed-cell foam is required for washability or to prevent biological material contamination, we design products from cross-linked polyethylene foams. Cross-linked foams are closed-cell, soft and tactile and come in a variety of colors. Some typical products made from cross-linked foams can be seen below:

Cross-linked PE can also be thermoformed to make unique medical products which are also closed-cell, durable and come in several different densities. The higher densities lend themselves excellent for Evo sterilization.

Open-cell foams also can be reticulated and used for filtering particulate in air streams. These two round filters are used in a medical application as a muffler to reduce noise in a procedure room environment. This product also meets 1099 approval due to the nature of the application.

Medical Foam Parts & Foam Die Cutting

Call to speak with a Design Engineer or Agent

Contact us Today (203) 488-4554