In response to increased demand, we are pleased to announce we are adding 40,000 square feet this year to our Connecticut facility. This will be done in stages, with approximately 10,000 in May staring the expansion. The additional space will house new equipment we will announce in the near future!

Foam Production Services

MPE Expands Production Capacity

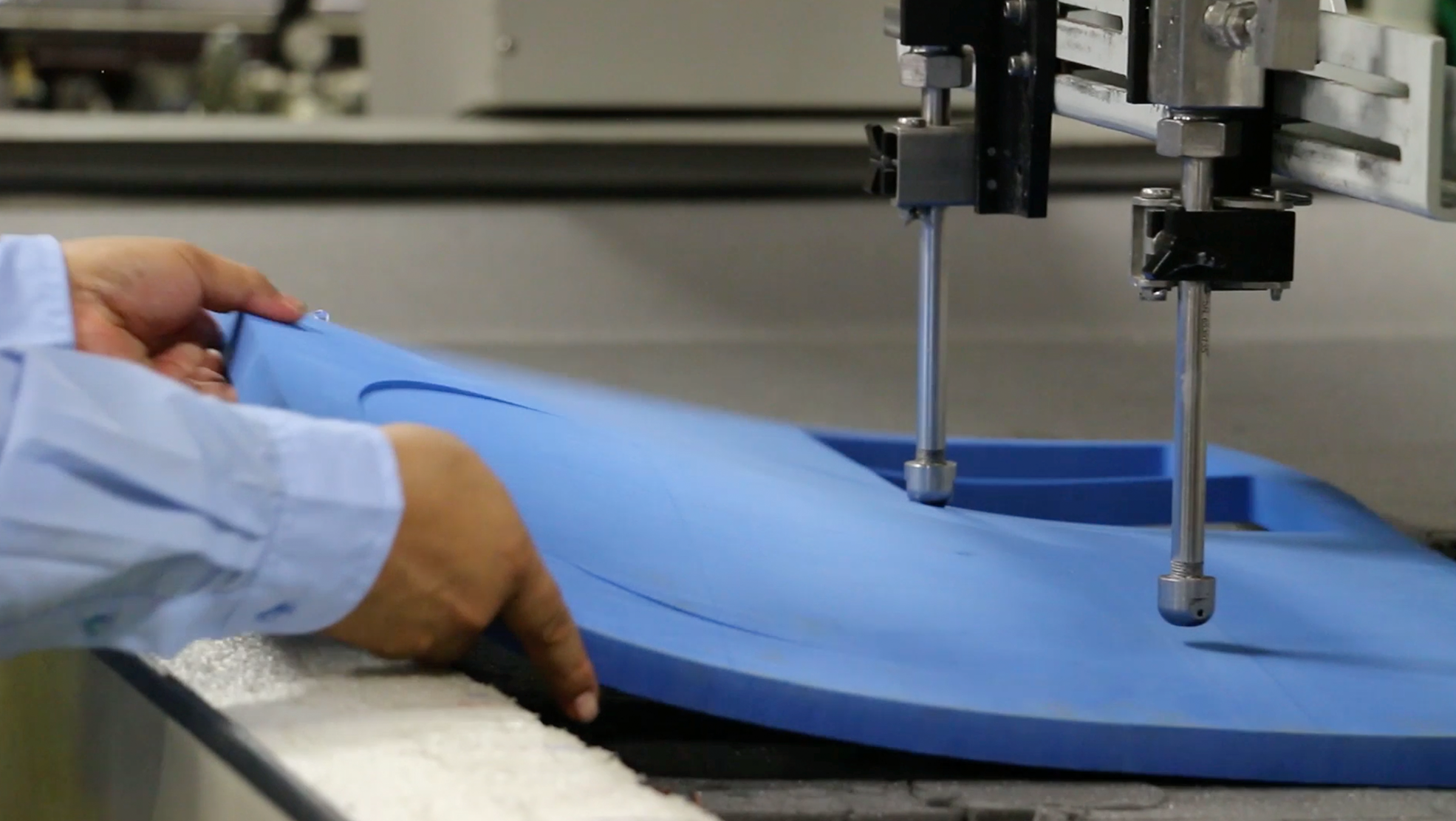

The completed installation of our new Baumer Precision Skiving Machine has been a high point for Madison Polymeric!

This machine has exceeded our expectations in providing extremely accurate skiving capabilities on high density XLPE, Bead Molded PE and PP along with 9# Extruded PE foam plank, and provides less waste and increases efficiency, as well as truly spectacular precision in your parts.

Please reach out to Madison Polymeric Engineering for help with your precision skiving needs.

Update on Pricing Fluctuations, Supply Chain

In our previous email to our clients, we detailed the issues associated with the supply chain issues the industry is facing, from not only a pricing standpoint but also availability. For example, urethan foam was being distributed only by allocation.

The good news is this appears to be softening, and pricing is beginning to level off. During this time , Madison Polymeric has worked to leverage multiple suppliers to maintain finished product delivery for our clients; at the same time, we are remaining cautious of price fluctuations in PE Foam, EPS Foam and paper board products.

Madison Polymeric to Add Pregis Custom Foam-In-Place Capabilities

Madison Polymeric Engineering (MPE) is excited to announce that we are now an authorized Pregis In-House Pre-Molder of custom engineered Foam-In-Place packaging in the New England market area.

For 2021, MPE continues to expand our protective packaging product offering to create a wide range of options in packaging solutions, providing increased protection with cost savings.

To this end, MPE has completed the installation of the latest generation of Pregis “On Demand” foam-in-place systems allowing us to offer a new Pre-Molded FIP solution to our customers. A foam-in-place production service for the in-house manufacture of custom designed FIP cushioning in low to large volumes where a Pre-Molded Foam In Place part is preferred.

The benefit to you is:

- An ability to see cost savings without the up-front equipment costs

- Manufacturing in a safe material environment

- Cost savings of a larger order for smaller demands

With this new option manufactured at our Branford facility, we can provide the perfect option for customers who do not have the space, time, or the volume to justify in house FIP molding production.

For more information on how the MPE design team can create packaging solutions to meet your needs, contact us today.

Water Jet Cutting

What is Water Jet Cutting?

A water jet cutter is an industrial machine that is capable of cutting a wide variety of materials using a very high-pressure jet of water. With the power behind the stream of water, this tool can cut a variety of shapes and sizes in the matter of minutes.

I have seen a water jet cut through wood, plastic, rubber, and foam. The precision is amazing and lines and edges are straight and clean. Water jet cutting is an asset to any foam converting company as it can perform a wide variety of cuts in various media, and leaves no distortion and no edge concavity. Depending on the material, the water jet can cut up to 8″ in thickness.

So, How Does it Work?

The water jet runs off of a computer CAD program which intakes the information, sends the file to the machine, and the jets cut the material into any shape that you draw. With a 60,000 PSI stream of water, water jet cutting can cut through thick materials. The water is stored in a self contained water purification system which reuses it over and over again. This method of recycling the water is sustainable and conserves on water usage.

Madison Polymeric Engineering uses water jet cutting for numerous applications. For more information ⇒ MPE Water Jet PDF

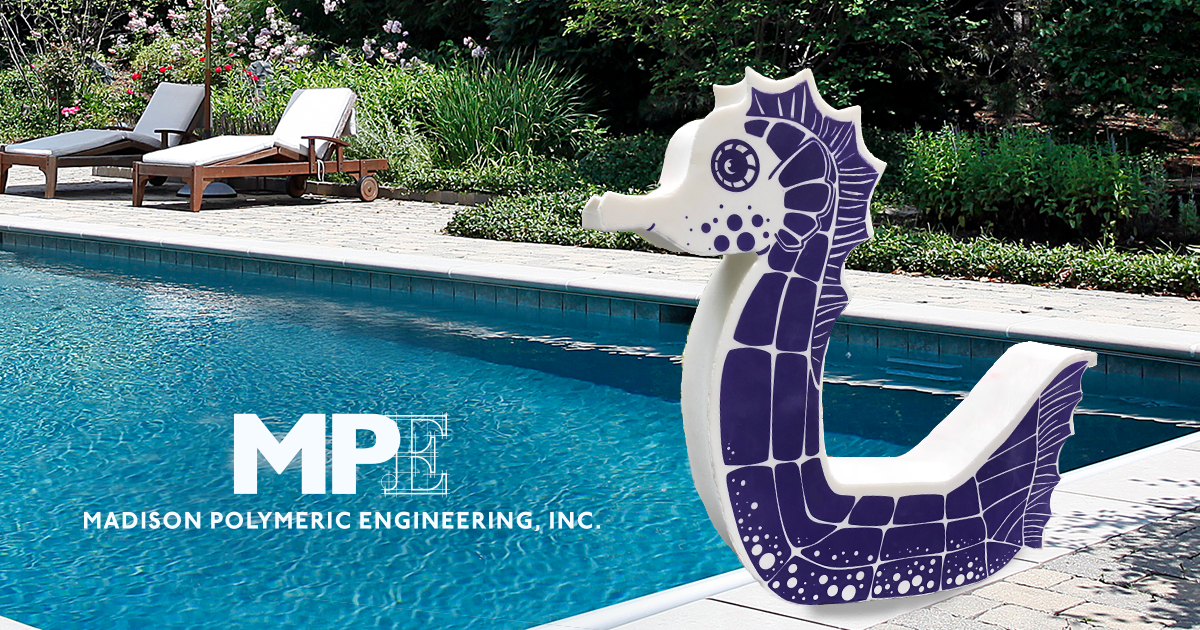

Foam Water Toys

Foam water toys are certainly a necessity during the dog days of summer. A quick dip in the pool , lake or ocean water refreshes and cools you off. But what if you would enjoy lounging in the water for awhile? Well then a flotation device could really come in handy. Cross linked Polyethylene, is a closed cell foam and does not absorb water, therefore, it is very buoyant. This pool toy floats in water and better yet, it floats with you on it. Besides cooling your body off on a hot day, there are benefits to swimming and playing in the water and you can’t beat that heat.

What are the Benefits of Swimming?

Numerous studies have proven how good swimming is for the body. For one, it takes the pressure off so if you are recovering from an injury, water therapy takes a lot of stress off from the injured part of your body while helping in the recovery.

According to swimming.org,

“No matter what your fitness level, the general benefits of swimming are yours to go out and grab and make your own. It has the power to give your muscles a makeover, transform you into a cardio king, turn back the clock, and calm you quicker than a secluded beach in the Bahamas.”

Continue reading the full article by Just Swim at → http://www.swimming.org/justswim/8-benefits-of-swimming/

Float your Boat…

If you are looking for a foam manufacturer to make a polystyrene float for your company, Madison Polymeric Engineering (MPE) is a company you can count on to get the job done Materials & Production Services . Engineers on staff, state-of-the-art equipment and on-time shipping, you can take your idea from paper to reality in a few short weeks. MPE has over forty years of experience in the Foam Industry. It may be nearing the end of the summer season but there’s plenty of time to create your product for Summer 2019.

Custom Foam Design & Die Cutting

Call to speak with a Design Engineer or Agent

Contact us Today (203) 488-4554