So, you need to ship your product across the country and you need to know that it will arrive safe, on-time and without damage. How will you begin this project? The first step is to find yourself a company with packaging engineers on staff that can design and engineer the insert that will suit your needs for shipping. You will need to decide the type of packaging that you are looking for. Perhaps you need foam to protect the part. The engineers will be able to suggest the type of foam you need, the density and the manufacturing type to produce the product. Whether it’s die cut, water jet cut or profile cut, to name just a few, be sure to find the manufacturer that can perform any style for you. Don’t forget to inquire about lead times. When will your product be ready for shipping after you place the order? These are questions you need to know.

Die Cut Packaging is a Proficient Engineering Solution

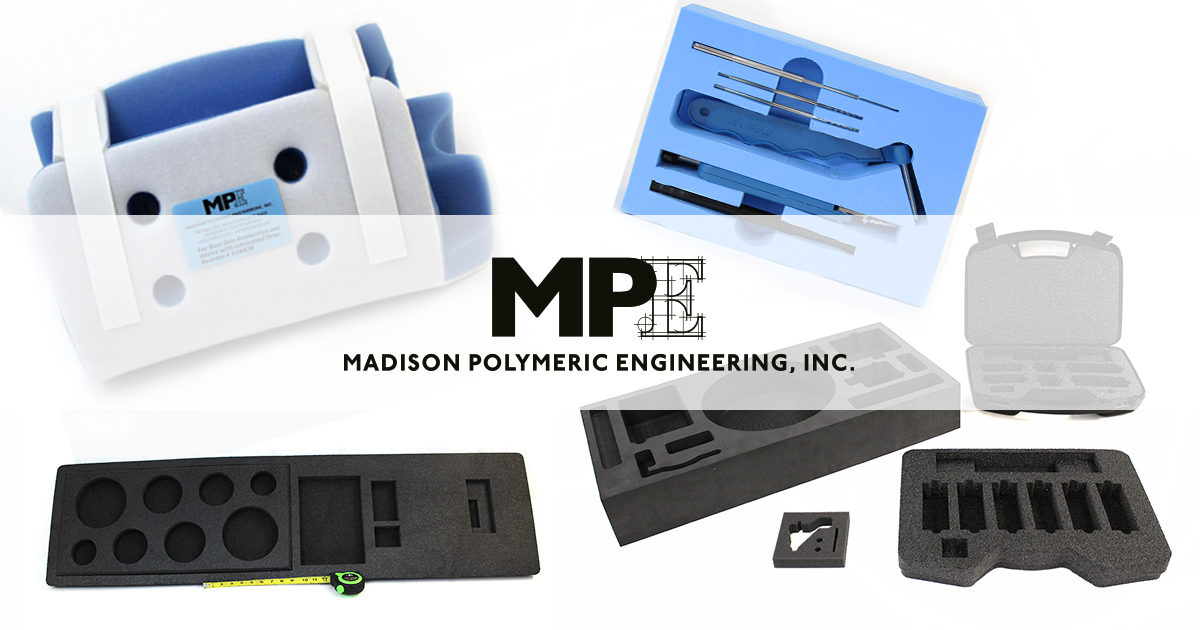

Madison Polymeric Engineering, https://www.madpoly.com, located in CT has the packaging engineers on-site that have the expertise to initiate and follow your project through to fruition. They have an abundance of foam in stock as well as the machinery to get the job done in a timely manner. MPE will provide samples, first articles, a timeline for completion and customer service through their sales team.

So You Might Want to be Sustainable?

Madison Polymeric Engineering is thinking sustainably by providing options for packaging. While all foam is recycled at MPE, there are companies that seek biodegradable packaging, hence the development of Molded Pulp Engineering https://www.moldedpulpengineering.com . Designing and engineering molded pulp opens the door to endless options for packaging that is 100% biodegradable, sustainable and compostable. It’s always nice to have options.

Contact a representative for custom die cut, water jet cut or profile cut applications.